TX800 four head inkjet printer system network interface inkjet board use for cylindrical printer

| Main Board Specifications | 182mm*112mm | Head Board Specifications | 198mm*132mm |

|---|---|---|---|

| Colour | Blue | Application Nozzle Model | 4720,W5113,I3200,TX800,XP600,DX5,DX7,7610 |

| Board Type | Inkjet Printer Four Head Control Board | Model | Tx800 Printhead |

| Use For | Industrial Inkjet Printer | Feature | Original And Brand New |

| Highlight | UV plate PET Film Machine Inkjet Board,Multipurpose PET Film Machine Inkjet Board,UV plate Control Board Kit |

||

TX800 four head inkjet printer system network interface inkjet board use for cylindrical printer

Quick details:

Name: Gigabit network inkjet board tx800.

Data interface: Gigabit network cable is connected to the computer, 1.25G optical fiber is connected to the spray car board.

Color channel: 6 channels/6 colors.

Number of nozzles: 1080.

Nozzle features: Can print water-based, thermal transfer, paint, eco-solvent, UV and other inks.

Board support: Single head, double head, three head, four head, eight head, sixteen head, thirty-two head .

Function support: Anti-collision and continuous printing, automatic height measurement, variable point printing, device power failure and continuous printing, USB automatic reset, USB disconnection and continuous printing, paper out detection, ink stack self-check, etc.

Application machine:

Elliptical digital machine, stamping painting machine,heat transfer machine, belt guide machine, carton machine, etc.

Oval digital printing features: simple operation, can realize automatic printing of multiple colors and patterns, comes with a drying function, the printing is not easy to damage, the printing quality is good, it can be combined freely, and the degree of automation is high. The ultimate printing effect on clothing provides an effective solution for digital application technology.

The main working process of textile printing and dyeing: fabric sizing, digital printer will spray the pattern on the fabric, oven high temperature drying, steaming, washing. Simplifies the traditional dyeing process, saving a lot of manpower, material resources and time. Use variable dot technology to make print patterns more delicate and colors more vivid.

Packaging printing is applied to the surface printing of various shapes and materials on site, whether it is porous or non-porous, flat or curved, fabric or ribbed surface, such as plastic, cloth, paper, fur, ceramic, glass or metal. At the same time, it is suitable for printing at various speeds, regardless of uniform speed, variable speed or intermittent operation, and is most suitable for continuous and non-stop production lines.

![]()

![]()

![]()

Application scenarios:

![]()

![]()

![]()

Water cup color printing Pants print Clothing printing

ADVANTAGE:

1. Research and Development team has been engaged in the development and research of industrial printing systems for many years.

2. We have a professional after-sales technical service team to ensure that your products are of better quality.

3. The company's products have been successfully applied in many industries, and have reached a high level in terms of color effect and printing speed efficiency.

4. We have a strict board test process to ensure that customers enjoy high-quality printing products.

![]()

Product Image:

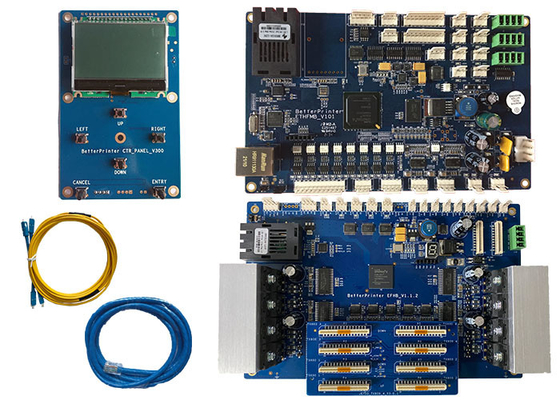

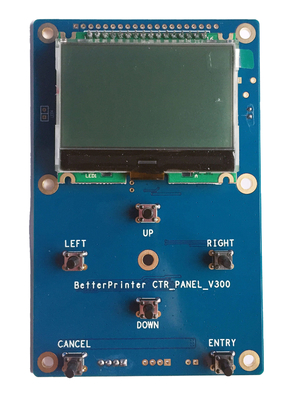

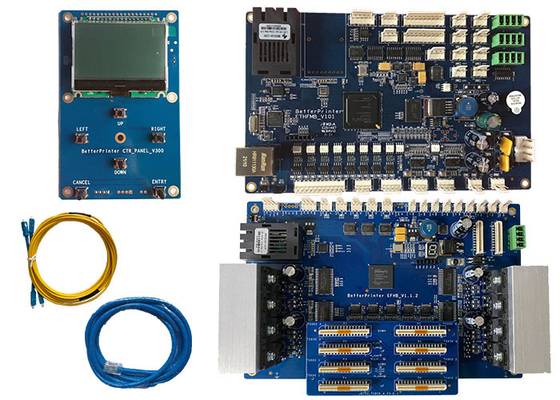

TX800 Inkjet Printer Board suit

![]()

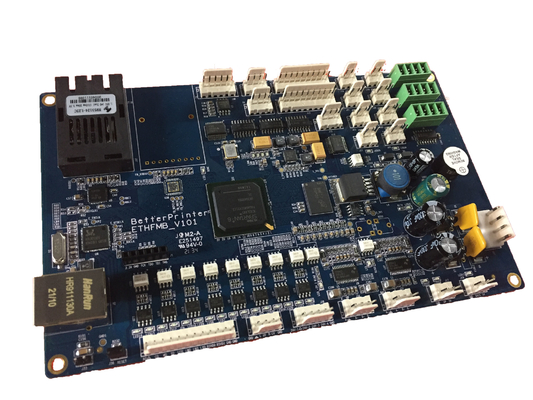

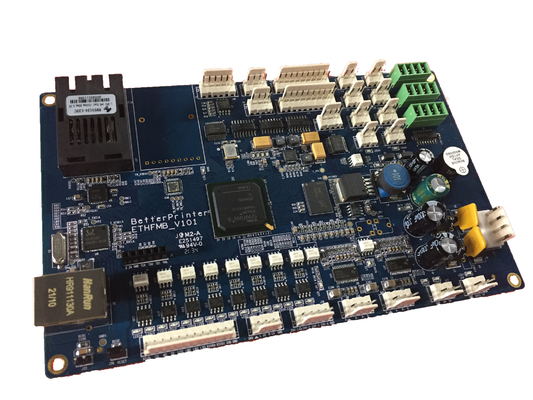

Main board

![]()

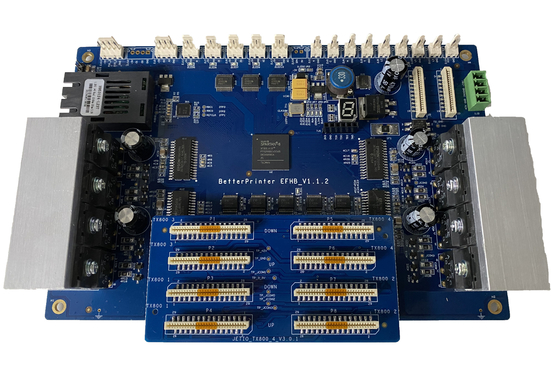

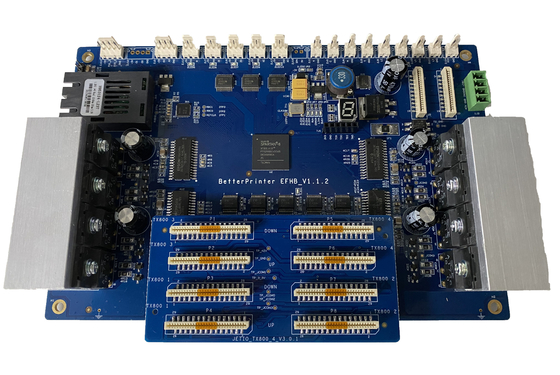

Head board

![]()

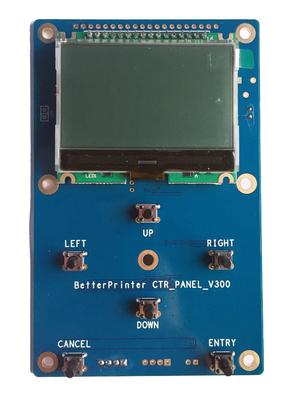

FAQ:

1. What kind of shipping method available?

we suggest sending by DHL express.

2. What is the way of payment?

You can via WeChat, Alipay, bank etc.

3. What is your after-sale service?

Warranty: one year warranty .

Technical support: online video technical support.

professional engineers, providing along the way.

Packaging and logistics:

Inner Package : bubble plastic bag.

Outter package : Carton.

![]() ⇒

⇒![]() ⇒

⇒![]() ⇒

⇒![]() ⇒

⇒![]()

![]()

![]()