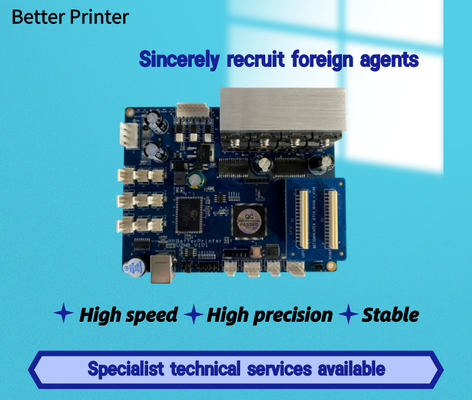

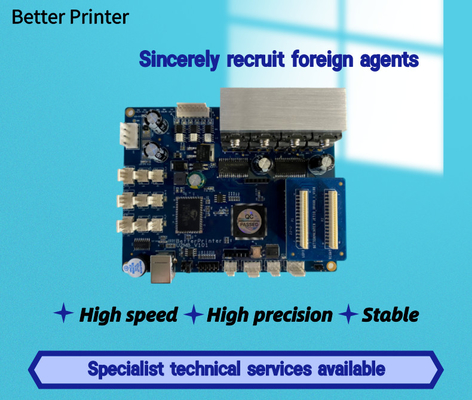

UV Printer I1600 Inkjet Board Printer System Glass Cylindrical Wine Bottle Cup Wine Packaging Box Inkjet Printer

| Product Name | I1600 Inkjet Board Kit | Board Type | Integrated Board Double Head Inkjet Board |

|---|---|---|---|

| Printing Type | Inkjet Printer | Printhead Model | I1600 Printhead |

| Use For | Industrial Inkjet Printer | Package | Anti-Shaking Package +Carton Box |

| After Sale Service | Provide Technical Support | Applicable Industries | Advertising, Textile, Packaging And Printing Industries |

| Highlight | Wine bottle cup Printer inkjet board,Glass cylindrical Printer inkjet board,UV printer inkjet board |

||

UV printer I1600 inkjet board printer system glass cylindrical wine bottle cup wine packaging box inkjet printer

Quick details:

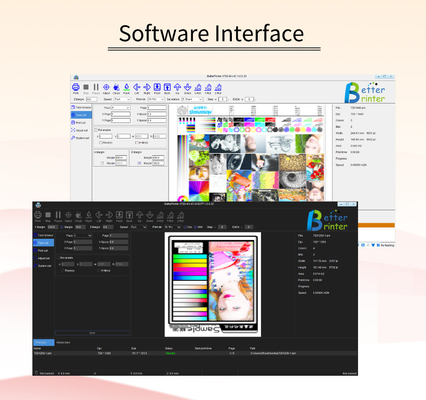

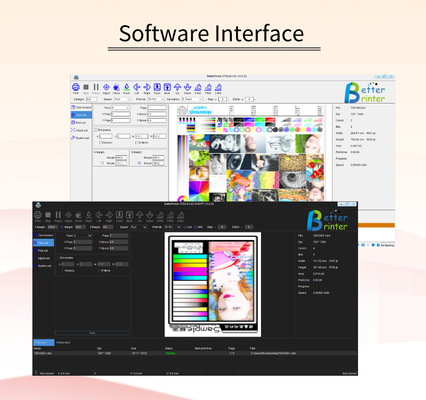

Integrated board inkjet printing control system, printhead: I1600, high cost performance. Provide various nozzle arrangements and spot color settings, such as staggered arrangement (staggered) full color, white color output at the same time, side by side, side by side 8 colors (kcmy+4 spot colors), etc. There are mature solutions for photo machine printing, UV flatbed printing, wall painting, floor painting, White ink pyrography Printer, etc.

| Inkjet board I1600 double head kit | |||

| Data trans method | USB cable to connect to the computer | Main Board | 1PCS |

| Support | UV Flatbed Printer, photo printer, White ink pyrography Printer, etc | Control panel | 1PCS |

| RIP-software | Mainstream RIP software such as MainTop, Photoprint, UltraPrint, ONYX, Wasatch, etc. | Adapter card | 1PCS |

| Technician | Online help | Print head ribbon cable | 1PCS |

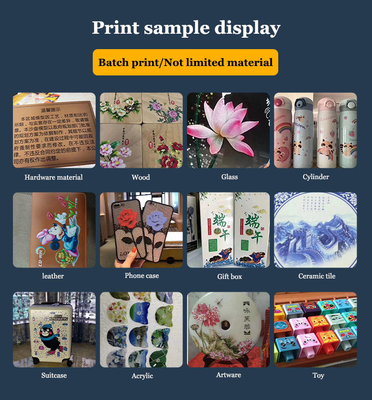

Application scenarios:

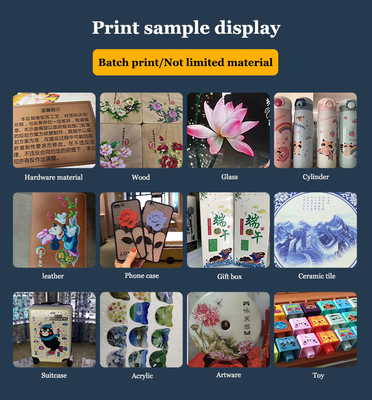

UV flatbed printer,White ink pyrography printer,Heat transfer machine, Wall printer,Spurt draws printer,etc.

Features of UV printing solution: easy to use and operate, no plate making and repeated color registration process, easy to operate and maintain. The use of environmentally friendly UV ink, spray and dry, stable printing, bright colors, high curing strength, low curing energy, environmental protection and no odor. The use of varnish can enhance the brightness effect of the image surface, and the adhesion of varnish on the surface of the image can also protect the image to a certain extent.

Packaging printing is applied to the surface printing of various shapes and materials on site, whether it is porous or non-porous, flat or curved, fabric or ribbed surface, such as plastic, cloth, paper, fur, ceramic, glass or metal. At the same time, it is suitable for printing at various speeds, regardless of uniform speed, variable speed or intermittent operation, and is most suitable for continuous and non-stop production lines.

![]()

Product Image:

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()