UV Printer I3200 Inkjet Board Crystal Label Pet Film Flat Printing Machine Acrylic Metal Wine Bottle PVC Printer Board

| Product Name | I3200 Inkjet Board Kit | Board Type | Optical Fiber Double Head Inkjet Board |

|---|---|---|---|

| Printing Type | Inkjet Printer | Use For | Industrial Inkjet Printer |

| After Sale Service | Provide Technical Support | Transport Package | Strong Export Professional Package |

| Shipping | DHL /UPS /TNT/ FedEx | Applicable Industries | Advertising, Textile, Packaging And Printing Industries |

| Highlight | Wine Bottle PVC printer board,pet film flat printing machine,i3200 inkjet board |

||

UV printer i3200 inkjet board crystal label pet film flat printing machine acrylic metal wine bottle PVC printer board

Product details:

USB2.0 optical fiber inkjet printing control system, application nozzle model: I3200, using optical fiber cable connection, fast transmission speed.For photo machine inkjet printing,UV flatbed printing, textile thermal transfer, textile film transfer, double-station direct injection, etc., there are mature solutions.

| USB2.0 inkjet board I3200 double head Inkjet Board | |||

| Data trans method | USB cable to connect to the computer | Main board | 1PCS |

| 1.25G optical fiber is connected to the spray car board | |||

| Support | Flatbed machine, belt guide machine, leather machine, etc. | Head board | 1PCS |

| RIP-software | Mainstream RIP software such as MainTop, Photoprint, UltraPrint, ONYX, Wasatch, etc. | Control panel | 1PCS |

| Technician | Online help | Moto board | 1PCS |

| Company | BetterPrinter Intelligent | Optical fiber | 1PCS |

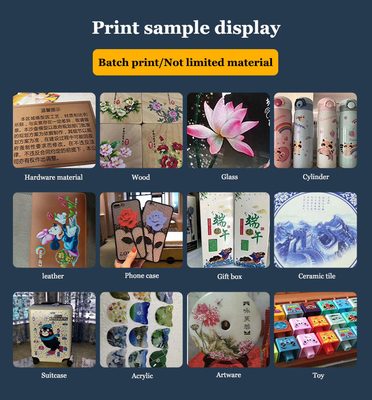

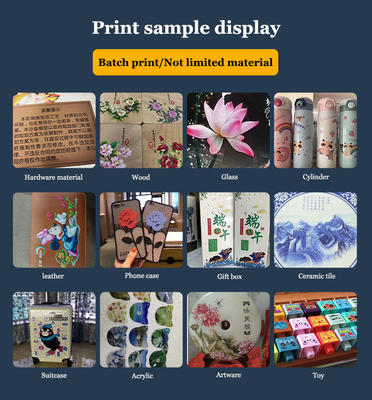

Application scenario:

UV flatbed machine,Photo machine, white ink scald transfer machine,double-station direct printing machine, etc.

Features of UV printing solution: easy to use and operate, no plate making and repeated color registration process, easy to operate and maintain. The use of environmentally friendly UV ink, spray and dry, stable printing, bright colors, high curing strength, low curing energy, environmental protection and no odor. The use of varnish can enhance the brightness effect of the image surface, and the adhesion of varnish on the surface of the image can also protect the image to a certain extent.

The main working process of textile printing and dyeing: fabric sizing, digital printer will spray the pattern on the fabric, oven high temperature drying, steaming, washing. Simplifies the traditional dyeing process, saving a lot of manpower, material resources and time. Use variable dot technology to make print patterns more delicate and colors more vivid.

![]()

Product images:

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Our Service:

We will provide more accurate and more efficient industrial inkjet printing control system research and development and services.

We have a professional after-sales technical service team to ensure that your products are of better quality.

We have a strict board test process to ensure that customers enjoy high-quality printing products.

We do 100% inspection before shipment.

![]()

![]()

![]()

![]()